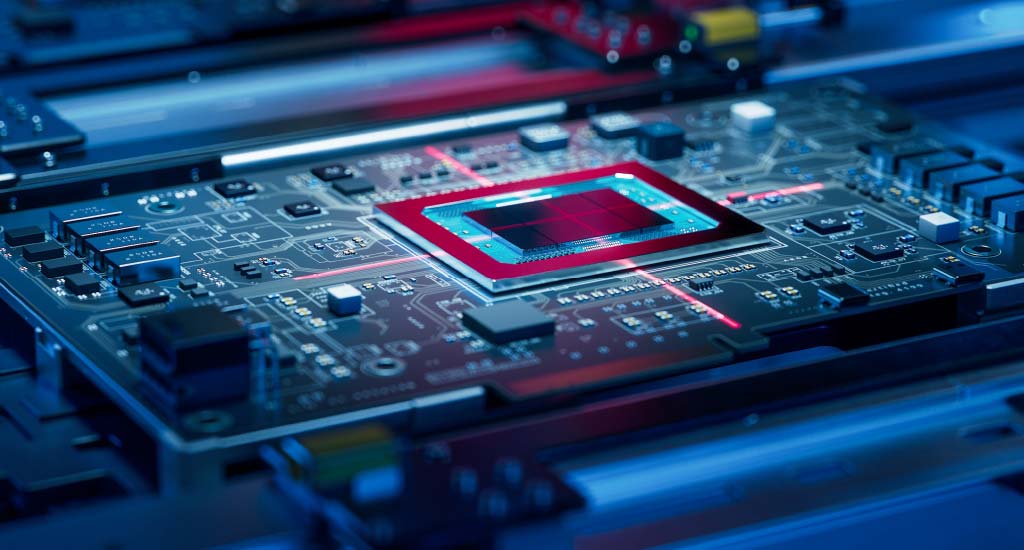

Controlling heat dissipation in hermetically sealed devices that house electronic components is a major challenge in the electronics sector.

Our thermal management materials including

Molybdenum-Copper (AMC) and

Tungsten-Copper (AWC), are engineered to deliver superior thermal conductivity and highly controlled thermal expansion. Critical applications include heat sink material, pedestals, and thermal spreaders

Preferred materials for GaAs and GaN Products

Due to their excellent thermal conductivity and controlled thermal expansion, our Molybdenum-Copper and Tungsten-Copper composites are the preferred materials for Gallium Arsenide (GaAs) and Gallium Nitride (GaN) semiconductors for the defense industry. Our heat spreader materials are trusted in sensitive applications such as:

- Advanced active radars

- Electronic countermeasures

- Jamming equipment

Sizes

Molybdenum-Copper and Tungsten-Copper material is available as finished parts with the following maximum dimensions depending on overall size

- Width: 4 inches (102 mm)

- Thickness: 3 inches (76 mm)

- Length: 24 inches (610 mm)

Our thermal management materials can be machined into shapes and readily plated and have superior through-thick-ness thermal conductivity versus other products. Furthermore, our ability to process into net shape and block form allow us to offer these materials for further machining into finished package products.

Tight Thermal Expansion Control

Heat spreader materials offer differing thermal expansion rates can be engineered to specific I/C materials. Although our Molybdenum-Copper and Tungsten-Copper materials are available in standard chemistry steps of 5%, we have the expertise to manufacture small volume custom engineered products to allow for very specific rates of expansion and customized compositions for CTE Match.

Turnkey Solution for Production Ready Pedestals

Our advanced thermal management materials are offered as raw material in sheet or block form. We also maintain the capabilities to vertically integrate for turnkey solutions customers in much the same way as our blended matrix products. We offer:

- Custom sized pedestals via Electrical Discharge Machining (EDM)

- High tolerance machining

- Nadcap™ accredited plating

- Pick & place packaging options such as waffle packs

- Burr-free edges

Applications

Our Molybdenum-copper and tungsten-copper composites are used in electronic packaging thermal management applications. These include:

- Chip mounting

- Heat sink material for naval, ground-based and aerospace radar

- Circuit board cores

- Lids or covers

- Heat spreader

- Semiconductors for the defense industry

- Electric countermeasures

- Jamming equipment

- Microwave Packages

- High RF Applications

- Laser Mounts

- Optoelectronics

- Nickel-Gold plated external power amplifiers

- 5G mobile internet network

Thermal management materials are used extensively as copper heat sink material & pedestals for integrated circuits (I/C) as well as the supporting cases for I/C packaging. We offer heat spreader material in cross-rolled sheet form for excellent x-y expansion properties as well as in pre-machined block form for I/C packaging.